TURBOCHARGERS

Turbochargers or, as we still say, turbo-compressors or turbines, slowly but surely have totally conquered the auto industry in the last two decades. In the area of ??diesel engines today virtually there are no aggregates without turbochargers. Better vehicle performances with lower consumption are the main guiding principle of engineers, and without turbochargers that’s impossible.

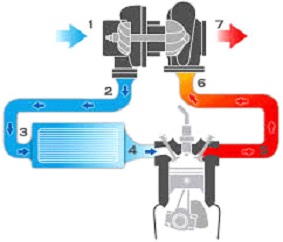

So, since in 1905, when the Swiss engineer Alfred Buchi invented turbocharger, and from the beginning of the application on locomotives and ships, across the planes and trucks, we have come to our today’s “companion” pets driven by the power of turbocharger compression. Each turbocharger is converting the heat energy of engine exhaust gases (6) directed through a turbine casing (7) into kinetic energy of turbocharger rotor. The turbine shaft is associated with the compressor wheel that rotates the same speed inside the compressor housing (1), after which compacting pressure occurs (2). To achieve a better effect of boost pressure, compressed air passes through the air cooler (3) so called “intercoller”.

PROBLEMS ON THE TURBOCHARGER

If there are symptoms of vehicle reduced power, black smoke, blue smoke, various strange sounds, increased oil consumption most likely you have a problem on the turbocharger. The problems occurring in the turbocharger can be caused in various ways. Poor lubrication, entry of foreign bodies in the rotor, the lack of oil in the engine, fatigue of turbocharger parts, clogging of intake and engine exhaust, the poor state of the engine in general… Repair of turbochargers in our workshop is done by all standards and the requirements of turbocharger manufacturers. The cheapest repairs usually doesn’t guarantee the longevity of your turbocharger, especially because the market is overflowed with suppliers of dubious quality spare parts.

Repair of turbochargers in our workshop takes place in the following manner. Upon receipt, the turbocharger is disassembled completely, and fault diagnosis is done. This is generally the most important step, because if the defect is caused due to irregularities on the engine, and that problem is not resolved, it would damage a new turbocharger as well. Then we carry out all depletion measurements of positions, a budget is estimated and then we contact the customer. If the customer decides to repair, continuing with repair of turbocharger includes the preparation of each position, from cleaning to blasting. Turbo core is assembled and placed on VSR balancing machine. The machine is able to balance up to 222,000 revolutions per minute. This guarantees the quality and durability of the turbocharger. After that, the core is placed in housing, adjusted are “Wastegate” valves or VNT geometry. Control is done with a machine to measure the flow of air. The turbocharger is delivered with a warranty card and instructions for installation. Contact us with confidence because we have thousands of satisfied customers so far and experience in this business since 1999. The warranty period on the repair of your turbocharger is 12 months.

English

English Hrvatski

Hrvatski